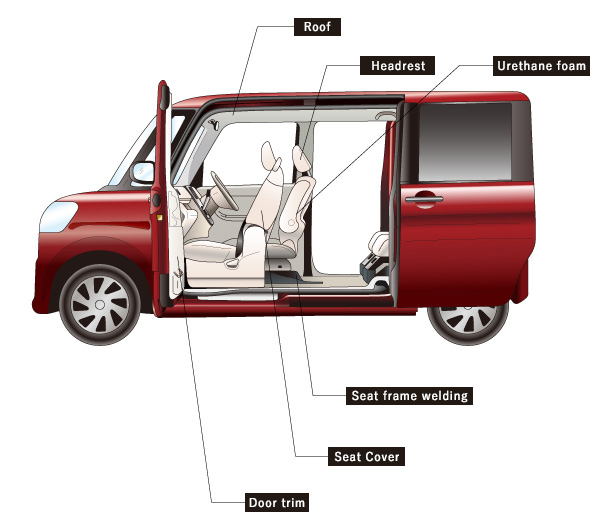

Automotive interior productsproduct

Futaba Sangyo manufactures automotive interior products. You can see each manufacturing process by clicking the button.

FSS(Futaba Sewing System)FSS

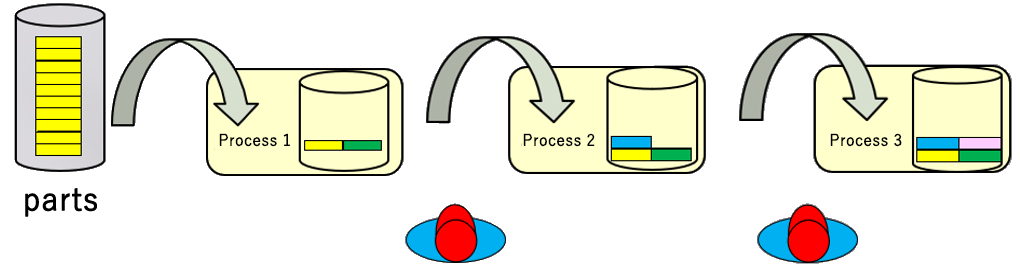

This system was born to eliminate the waste of overproduction and was introduced early in the sewing of automobile seat covers.

At FSS, we have adopted the “one-piece flow production” method, in which parts are processed one by one in the order of the process, and then sent one by one to the next process in order.

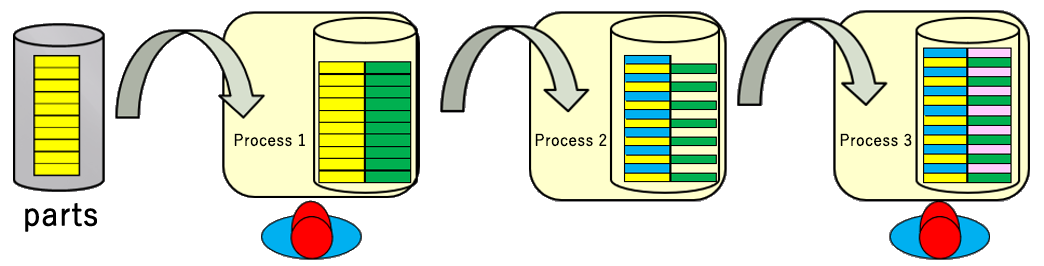

Lot sink (accumulated sink)

It is a method to finish one process and move to the next process.

FSS production method

1 piece flow production

It is a method in which products flow one by one.

Advantages of FSS

-

01. Just In Time

We can produce what you need, when you need it, and in the amount you need. -

02. The line flows rhythmically

Since it is the same work, the tempo will be better -

03. Be able to improve production waste

Wasteful work and waste can be reduced because only the necessary amount is produced. -

04. Can train multi-skilled workers

Mutual help (relay zone) is set up, so multi-skilled workers are possible -

05. Leads to cost reduction

You can eliminate the waste of making too much by making one sheet. -

06. Leads to quality maintenance and improvement

Defective products can be found in units of one, and countermeasures can be taken quickly. -

07. Can be produced in a shorter time than lot production

Able to meet short delivery times -

08. Less in-process inventory

You can switch products faster than lot production, and you can quickly respond to plan changes. -

09. Eliminates the need for space for in-process inventory

Shorter production lines and more efficient use of space